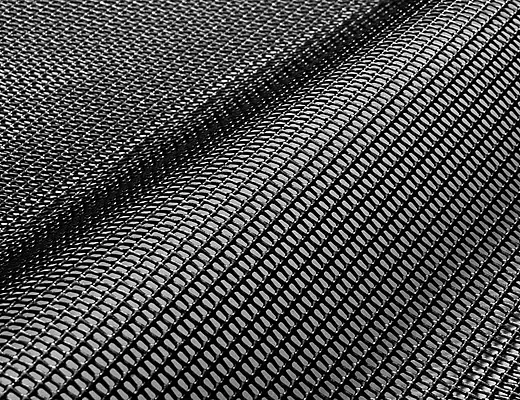

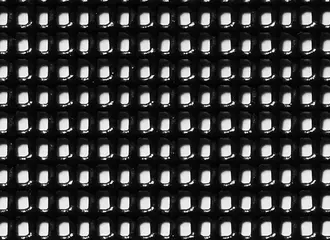

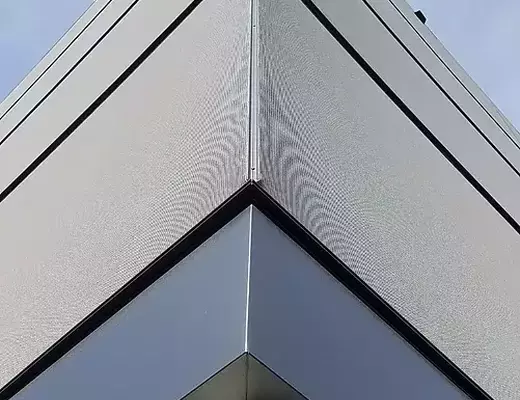

Does your mesh have a 50% Openness Factor?

Architects and engineers understand that the National Building Code requires any open parking garage to be at least 20% open. Britten has conducted comprehensive testing to assure that our products offer 51% openness factor.

It should be noted that when calculating the 20% open factor, you must consider all solid walls, bulkheads, low-walls, columns, and any other solid features of the design that restricts or prevents airflow.

Britten can advise the proper mesh to use on your structure to meet the "openness" requirements of your jurisdiction.

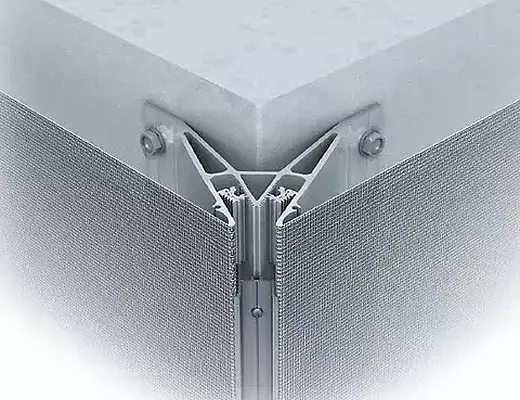

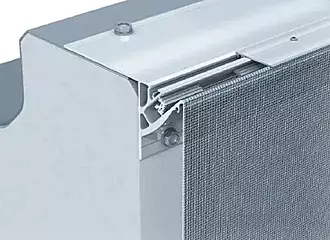

What are PTFE and PES, and what do they mean for building façade projects?

PTFE stands for "Polytetrafluorethylene," fabric and has been utilized for years in tensile architecture. Known for its flexibility, the fabric is ideal for projects requiring malleability such as retractable roofs. Due to the chemical makeup of the fluoropolymer coating, it is highly resilient against environmental and exterior exposure. PTFE is best suited for small and mid-sized projects and is often employed for roofs, facades and other retractable applications.

PES stands for "Polyethersulfone" fabric which is more commonly known as Polyester Scrim. The base material is a woven high tenacity polyester scrim with a flexible PVC coating that encases the polyester fibers on all sides.

Britten TexClad™ typically uses PES which includes silicon-like polymers to provide superior dirt repellence, fire retardancy and protection for UV-exposure fading. This makes the open mesh fabrics, durable, light, air-permeable and highly durable to extensive exterior exposure.

Open-mesh fabrics can accept a wide array of colors and tensile strengths and are becoming increasingly popular for fabric façade applications, and are the most economical material in tensile fabric and membrane architecture.

How do you suggest we clean our TexClad™ Fabric Façade?

Our façade fabric is coated in a substance similar to "Rain-X™," meaning it inherently repels the adhesion of dirt, dust, fungus, mold, and mildew.

Due to the proprietary coating, natural rainfall will assist in cleaning the façade surface. For a more direct cleaning, a simple solution of soap and power-washing every 3-4 years will keep the fabric looking clean and fresh.

Does Britten’s TexClad™ system satisfy LEED requirements for architects?

As an architectural façade system which covers the exterior of the building, TexClad™ helps satisfy LEED initiatives by:

- Reducing overall heat gain and loss

- Reducing solar glare and solar gain

- Reducing energy costs that laser-cut metal panels require

- Reducing the weight by as much as 90% compared to metal facades

How does the TexClad™ warranty work?

Unlike most architectural graphic warranties, Britten Inc is offering a full replacement of any mesh panels that have been properly maintained and that may be damaged, or faded due to natural elements, excluding weather deemed extremely severe by the National Weather Service, including:

- Wind

- Rain

- Ultra-Violet Exposure

- Fungus

- Mold

- Mildew

The Britten difference is that the Britten warranty is not a scaled warranty—meaning it does not depreciate over time. Britten is a fully vertically integrated company, meaning we control the entire process and dictate our own terms, including our own warranty. In comparison, our competitors rely upon subcontract for printing, fabrication, and installation and must adhere to numerous and varying warranty standards for each product and process.

The Britten Promise is that if your TexClad™ façade is damaged or faded by any natural causes, Britten will repair or replace the fabric and/or hardware at no additional charge for the full term of the warranty assuming proper annual maintenance has been upheld.

*Damage not covered by our full warranty includes damage caused by vandalism, smoke, or fire, or damaged caused by hurricane force winds.

Does TexClad™ meet all flame-resistance and/or non-combustibility requirements?

Yes, TexClad™ high-strength engineered textiles are non-flammable and meet the requirements for fire protection class A2.

Are there limits to what can be printed?

No, the possibilities are nearly limitless. All solid color, pattern and full photographic printing is produced by Britten high-resolution digital printing resulting in high quality and vibrant imagery on all textile materials.