Building Wrap Vs. Scaffolding Wrap

What’s the difference and process for creating and installing one? Read on…

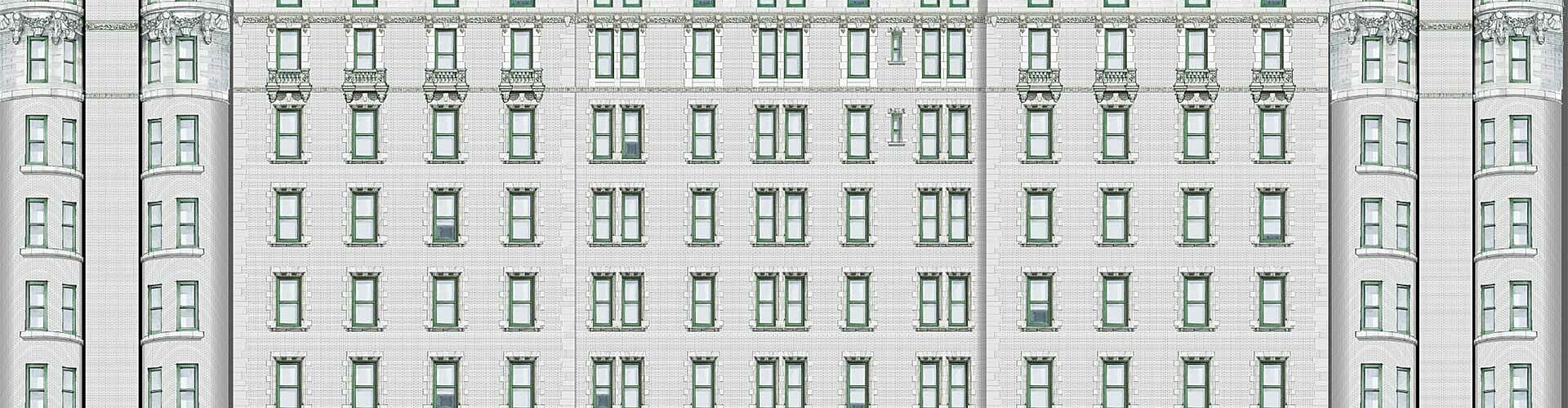

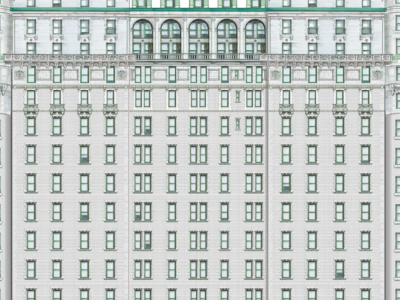

HAVE TO THANK ARCHITECTURE AND DESIGN REPORTER, Jane Margolies, for this one. While working on this recent New York Times story about scaffolding wraps, Margolies reached out after research led her to another NYT’s story about the 2013 facelift of Manhattan’s iconic Plaza Hotel and the massive wrap Britten printed and installed to cover the renovation.

Margolies had a couple basic questions—What’s the difference between a building wrap and a scaffolding wrap? And what’s the process for ordering and installing one? Since other people probably wonder the same thing, we thought the following post would help.

In the early 1970s, after introducing a new non-woven moisture-barrier material called Tyvek®, DuPont popularized the term “building wrap” in the construction industry. Today, the term also describes large vinyl banners that are bolted directly to the masonry walls of building.

As the world of digital Inkjet® printing evolved in the mid-1990s, advanced applications such as extra-large decals, perforated window films, and a variety of vinyl and mesh fabrics were used to print and fabricate building wraps to conceal unsightly aspects or to display advertisements.

While similar in material and camouflaging function, scaffolding wraps made of Britten’s unique Architectural Mesh™ technically differ in that they attached directly to scaffolding outside the building. Scaffolding wraps are printed on 50-70% open mesh that has been flattened to receive ink on the visible surface and are essentially transparent to the building occupants.

A common practice for decades among contractors in Europe, hiding ugly scaffolding with beautiful and interesting Architectural Mesh imagery is fast becoming in vogue here in the U.S.A. Nearly all cities require contractors to install mesh over scaffolding to meet safety protocols and to prevent any construction debris or tools from falling to the sidewalks below.

SIMPLE PROCESS. REMARKABLE RESULTS.

How is a wrap created and installed? Whether talking about building or scaffolding wraps, no two projects are ever the same. But after 35 years covering everything from high-rise structures, museums, hospitals, and everything in between, Britten has landed on a proven process that works regardless of the project’s scope or architectural challenges.

STEP 1

A building owner or contractor who wishes to dress up an unsightly building or construction zone contacts Britten to request a quote. After providing general sizing, specs, and technical details, a phone call with a Britten rep is set up to discuss the type of artwork the customer wants to display and the initial pre-quote.

STEP 2

Most customers supply their own digital files of the artwork they intend to use, some come to Britten with nothing more than an idea. NYC’s Plaza Hotel and Himmel + Meringoff Properties recent major renovation of 411 Layfayette are just two examples of the unique building facades and original decorative designs hand-drawn by Britten’s owner and founder, Paul Britten.

Regardless of the customer’s need, a sample of the artwork is delivered. Budgetary considerations and the overall look of the design is also approved by the customer in this phase along with the sending of a deposit to cover costs of production and (where applicable) installation by a Britten crew.

STEP 3

Once the final go-ahead is given, the proofing process begins. A site survey is also conducted by the install team to determine how the wrap will be securely attached. For scaffolding wraps, scaffolding blueprints are necessary to ensure proper fit and anchor placement.

Proofs are then sent to the client with full fabrication and artwork to scale and, once approved, the printing and install team works together with the contractor or building owner to get the job finished on time.

Timing of entire process start-to-finish? Regardless of the structures size—high-rise building, museum, or hospital—Britten has completed projects, start to finish, in as little as a week. But it typically takes about a month or more depending on how quickly the customer provides final sizing and production approval and acquires the necessary permitting for installation from their local municipality.

Talk to us about transforming your worksite by submitting a quote request or by calling 855.763.8205. To get more answers to questions our customers ask the most, see Building Wraps: Read Before You Buy.