The Innovation of Dye Sublimation

Print that's to dye for! Learn the ins-and-outs of dye sublimation and how Britten is using it to make lasting impressions!

Sublimation may have a familiar ring to it. Chances are it’s a term still rattling around your brain from that chemistry class way-back-when! Your teacher took out a chunk of dry ice and in a wisp, it appeared to evaporate into thin air—that’s sublimation! It’s when a solid bypasses the liquid state and enters right into a gaseous state. That’s the idea behind dye sublimation—an innovate digital printing technology. Learn more about how the dye sublimation process works and how Britten employs large sublimation printers to create massive and lasting fabric prints!

How Does Dye Sublimation Printing Work?

There are two common methods of dye sublimation printing—transfer and direct dye sublimation printing.

Transfer printing works by having graphics printed onto a special transfer paper using a large sublimation printer and inks. Next, a heat press is used to transfer the ink from the special paper onto the selected substrate.

Direct dye sublimation (also known as direct-to-fabric printing) functions by eliminating the need for transfer material and printing directly to the substrate. These printed fabrics are then run through a calendar (heat press) to bind the dye to the fabric. Due to this reduction of steps and materials, direct print is often more cost effective and efficient to print.

The method of dye sublimation printing used depends on the project, the graphics being used, and the substrate that is receiving the print. A leader in custom dye sublimation printing, Britten is equipped and well-versed in both methods of printing ensure that you receive the optimal print work for your specific needs!

What’s The Advantage of Dye Sublimation?

Since the solid dye is converted directly from a solid to a gaseous form through heat (hence why it’s called sublimation), it creates a greater bond to the substrate. Achieved through the application of heat and pressure, the dye penetrates into the substrate, creating a permanent and lasting bond.

As opposed to colors that are simply printed on the surface of a substrate, dye sublimation embeds the colors into the fabric making the transferred image nearly impervious to fading or cracking!

Why Use Fabric Over Vinyl Material?

The choice of fabric or vinyl printed material really comes down to application. Fabric printed work is often ideal for indoor display and print work. Due to the nature of the substrates, fabrics can embody a softer finish, accommodate vibrant color, and is an elegant option for large format graphics.

It weighs almost 75% less than vinyl (meaning it costs less to ship) and is easier to store for seasonal applications. Perhaps the most distinct advantage is that fabric can accommodate backlit applications like Britten’s backlit banner frames, which provides a soft glow and alluring appeal to any display.

What Fabric Is Right For You?

Equipped with a robust arsenal of printers for sublimation printing, Britten also offers a wide array of substrates and fabric products. Specializing in custom sublimation printing, Britten provides vibrant imagery paired with the perfect material to suit your particular branding needs! Here’s a shortlist of some of the most popular fabrics to consider for your next project:

1. Display Knit Fabric

Display knit is a reliable all-purpose material that is ideal for tension fabric displays like the Britten silicone-edge graphic (SEG) frames and beyond! Ideal for single-sided displays, indoor branding and advertising and trade show displays, display knit is exceedingly versatile.

Made from direct-to-fabric dye sublimation, this fabric offers vibrant print quality with a high-end matte finish and is one of Britten’s most popular materials

2. Blockout Knit Fabric

As the name implies, blockout knit fabric is optimal for curtailing distracting light and is perfect for stage backdrops and presentation backgrounds. Despite being an opaque fabric, blockout knit is still made with direct-to-fabric dye sublimation, meaning it can also accommodate vibrant colors and graphics, making it an ideal custom display with functional appeal.

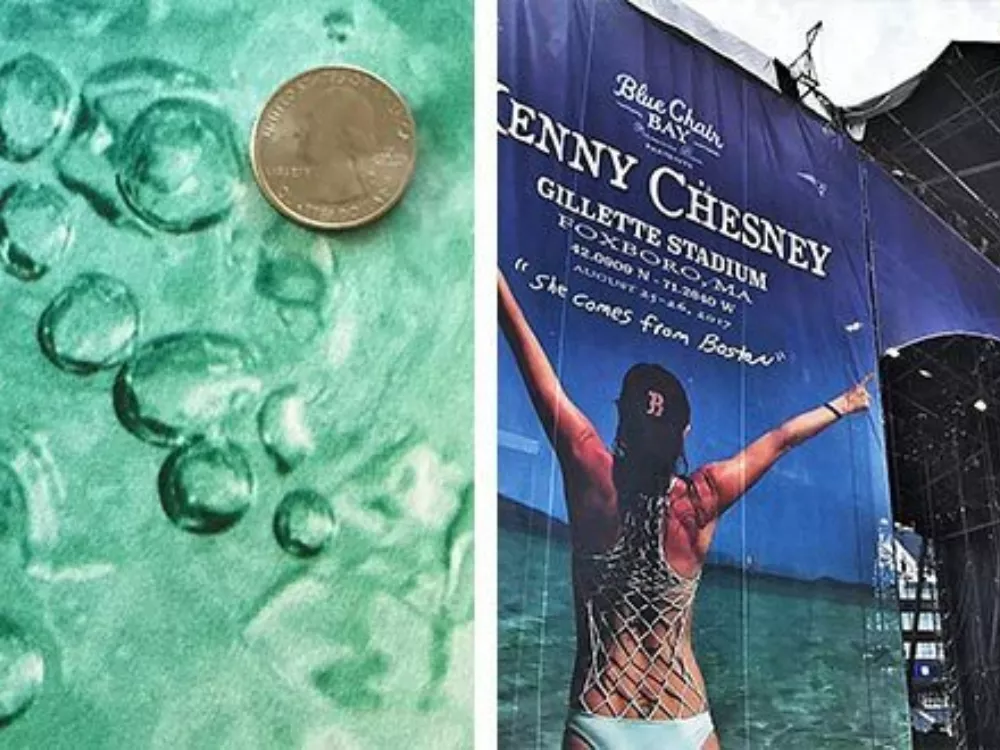

3. Backlit Knit Fabric

Lightweight and semi-translucent, this fabric is made to work in tandem with framed LED backlit display frames. Also crafted with direct-to-fabric dye sublimation, this light material accommodates vivid imagery and branding that results in an alluring presentation once illuminated. Manufactured for most backlit applications, this knit fabric works well with LED displays, backlit stage drops and lighted fluorescent displays.

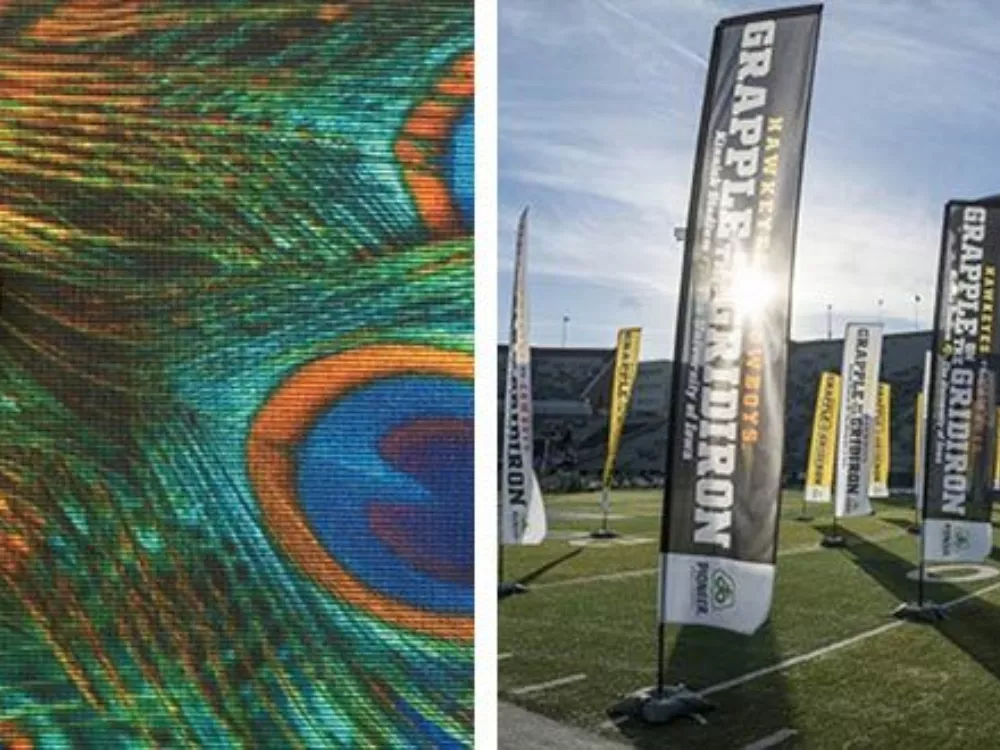

4. Flag Knit Fabric

Tailored toward flag applications, this dye sublimated material is made to proudly waive in the breeze. Perfect for indoor or outdoor use, this lightweight, sheer polyester is easy to manage and can display a reverse image on the backside. Paired with Britten’s large sublimation printer capabilities, flag knit can be scaled to massive proportions in order to fabricate gigantic banner displays and even entire building wraps.

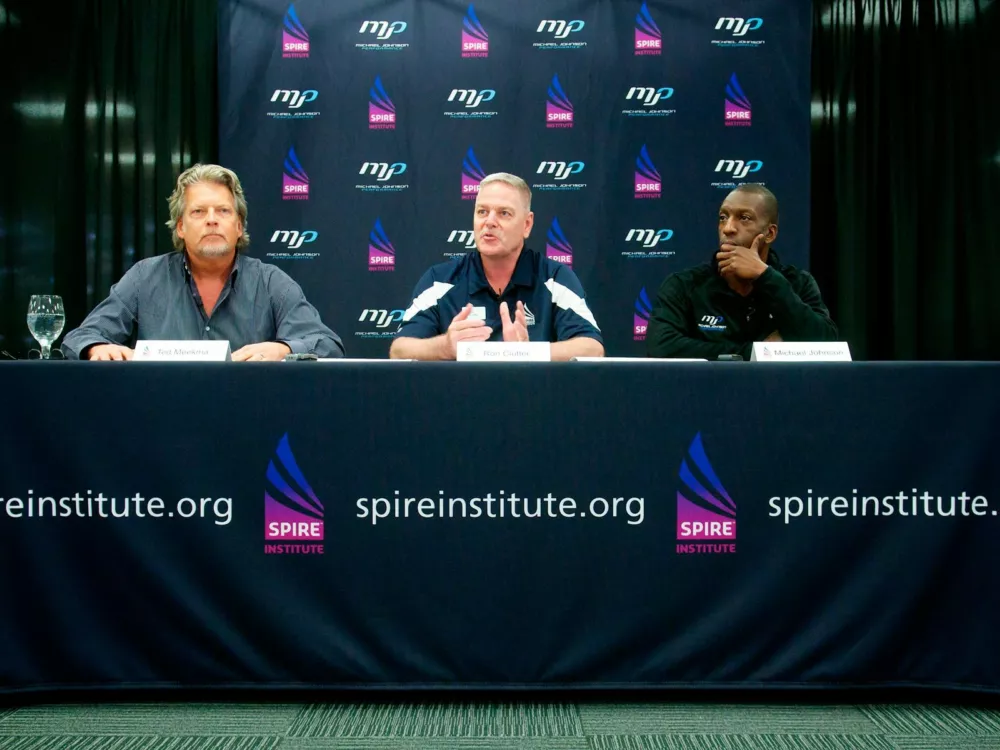

5. Soft Knit Displays

Consisting of a medium-weight material, soft knit is a cost-effective, highly wrinkle resistant material with numerous applications. Rounded off with a sleek satin finish, soft knit is the ideal material for table throws, trade show displays, and even some brand banners and backdrops.

6. Powerstretch Fabric

A premium tensile fabric, powerstretch is made to expand and conform to shape. Boasting an attractive no-glare matte finish with wrinkle resistant properties, powerstretch works well with banner display frames, popular “pillowcase” frame covers, and SEG frames where added elasticity is desired.

Make a lasting impression with Britten and dye-sublimation printing! Contact Britten for a custom quote or for more information email [email protected] or call 855-763-8203 to speak to a sales rep.